Ultrasonic Cleaner Full-automatic Multi Tanks Conveyor Design Through Type Cleaning Machine

Original price was: $56,000.00.$49,000.00Current price is: $49,000.00.

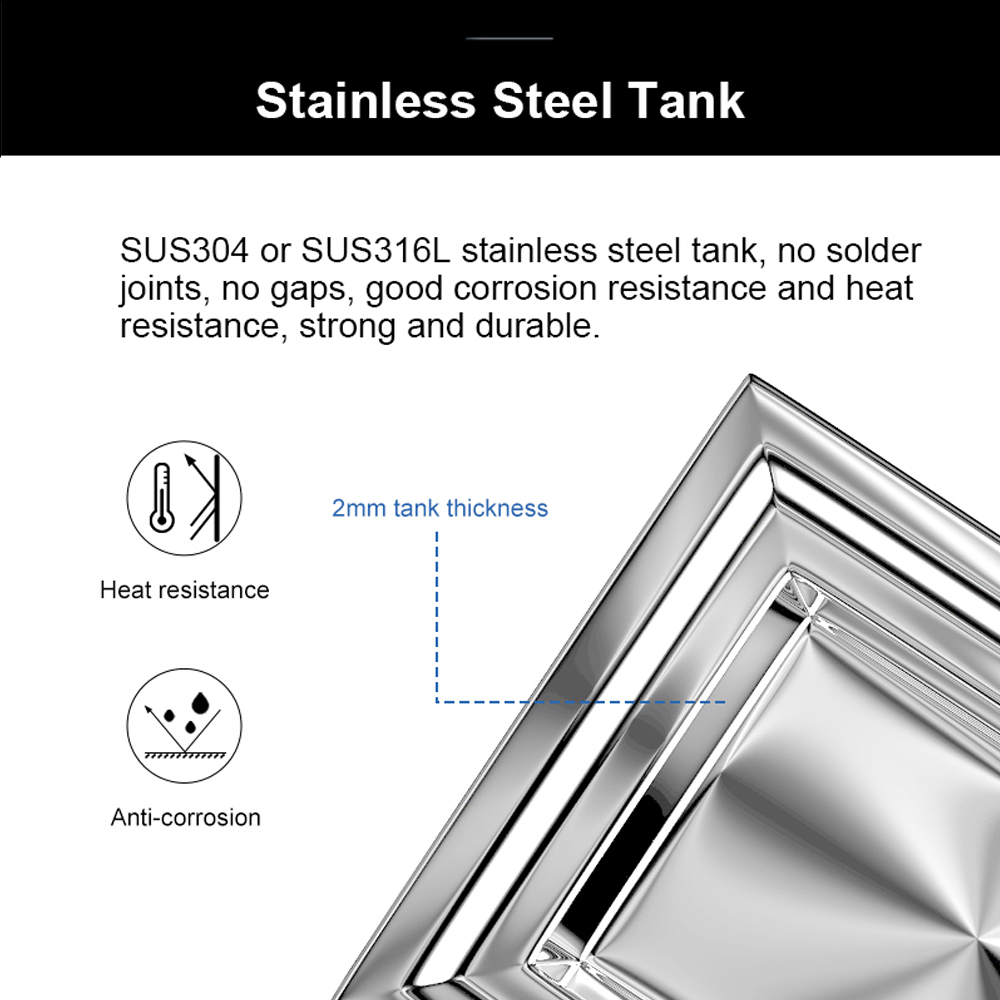

1. Unit size: 10050*1300*1800mm, tank material is stainless steel SUS316L.

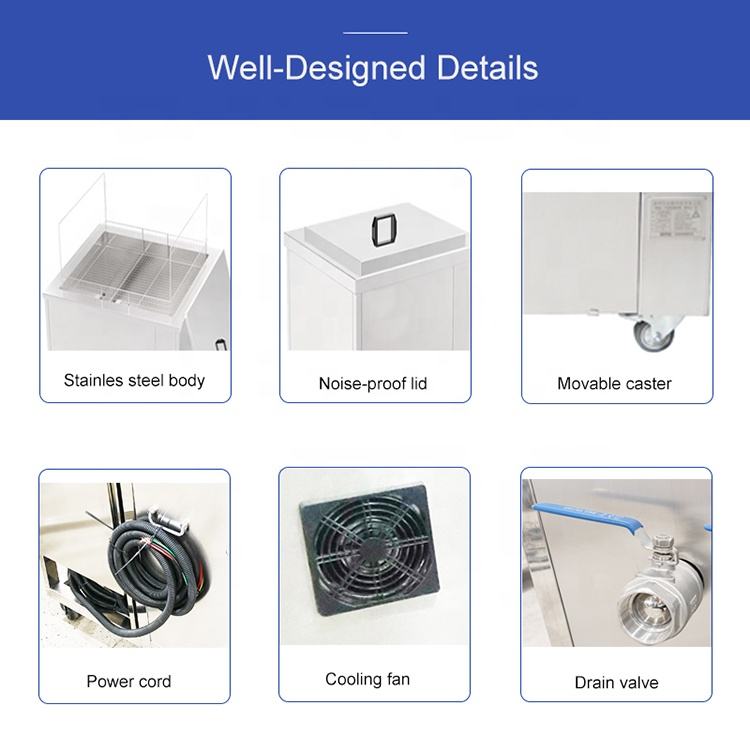

2. Conveyor belt: stainless steel herringbone with baffle chain net, the center distance between the chain at both ends of the net belt is 350mm, the speed is 300-1000mm adjustable, the power shaft end is configured with torque limiter, and the motor is 400W 200:1 horizontal gear reduction motor.

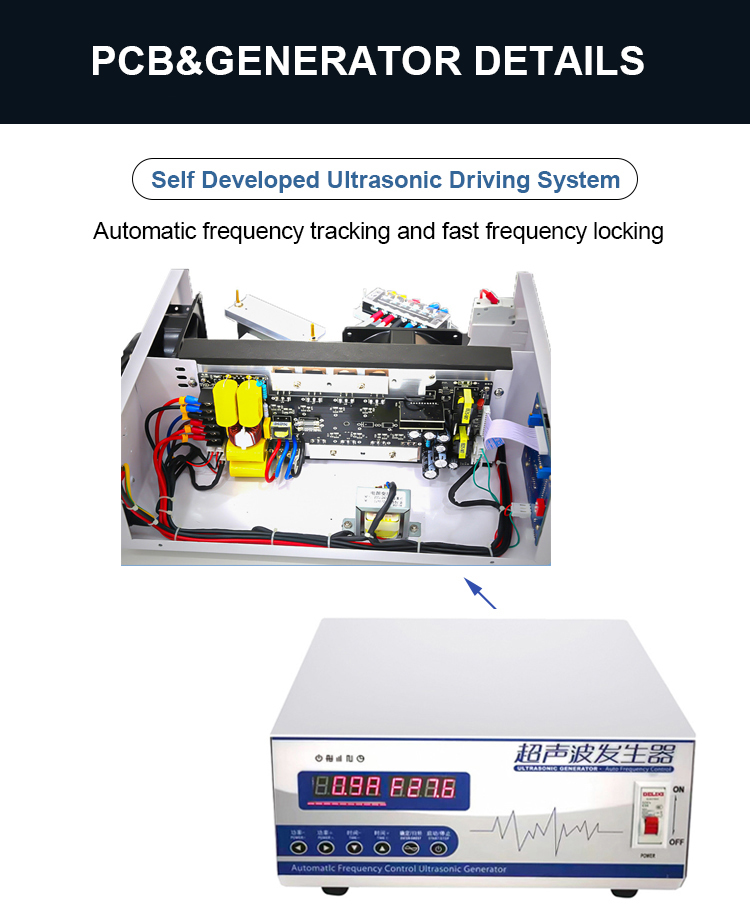

3. Ultrasonic system: the 1st tank is equipped with 3 sets of vibration plate, the 3rd and the 5th each tank is equipped with 1 set vibration plate. Each vibration plate power 1200W, frequency: the 1st to 3rd tank is 28khz, the 5th tank is 40khz, total ultrasonic power: 6000W, with independent generator, The power is adjusted according to the production process, the 1st tank is configured with 9KW heating system, the 2nd tank is configured with 6KW heating system, and the other slots have no heating system.

4. Spray system: the 4th tank is spray cleaning, and the 6th tank is spray rinsing.

5. Air cutting drying system: the 7th tank is the air cutting system, and the 8th tank is the circulating hot air drying system. It is equipped with two sets of 9KW air heaters, and the internal circulation air supply ensures the reduction of heat loss and the purity of hot air.

Need some help?

Contact Us

Lush Trees Tech Ultrasonic Cleaner Full-automatic Multi Tanks Conveyor Design Through Type Cleaning Machine

1. Inner tank size: It can be customized according to customer's product size & cleaning quantity.

2. Ultrasonic power: It can be customized according to the cleaning tank capacity. The larger the capacity, the more ultrasonic power is needed.

3. Ultrasonic frequency: 20khz / 25khz / 28khz / 35khz / 40khz / 60khz / 68khz / 80khz / 168khz / 200kHz can be optional. 28khz and 40khz is most commonly used.

4. Ultrasonic generator: There are split-type and integrated type, can be optional.

5. Ultrasonic direction: Bottom shock and side shock. Bottom shock is the most commonly used.Transducers can be installed at the bottom and side if the product is bigger and structure is more complex.

6. Inner tank material: Stainless Steel SUS304 / SUS316, the most commonly used is SUS304, we kindly recommend to use the stronger acid alkali SUS316 if the cleaning agent you will be used is strong acid or strong base.

7. Outer plate material: The material has drawing plate and mirror plate optional. Commonly used is drawing plate.

8. Stick Brand: We can stick the customer brand according to the authorization of the customer. The default is LUSHTT Brand.

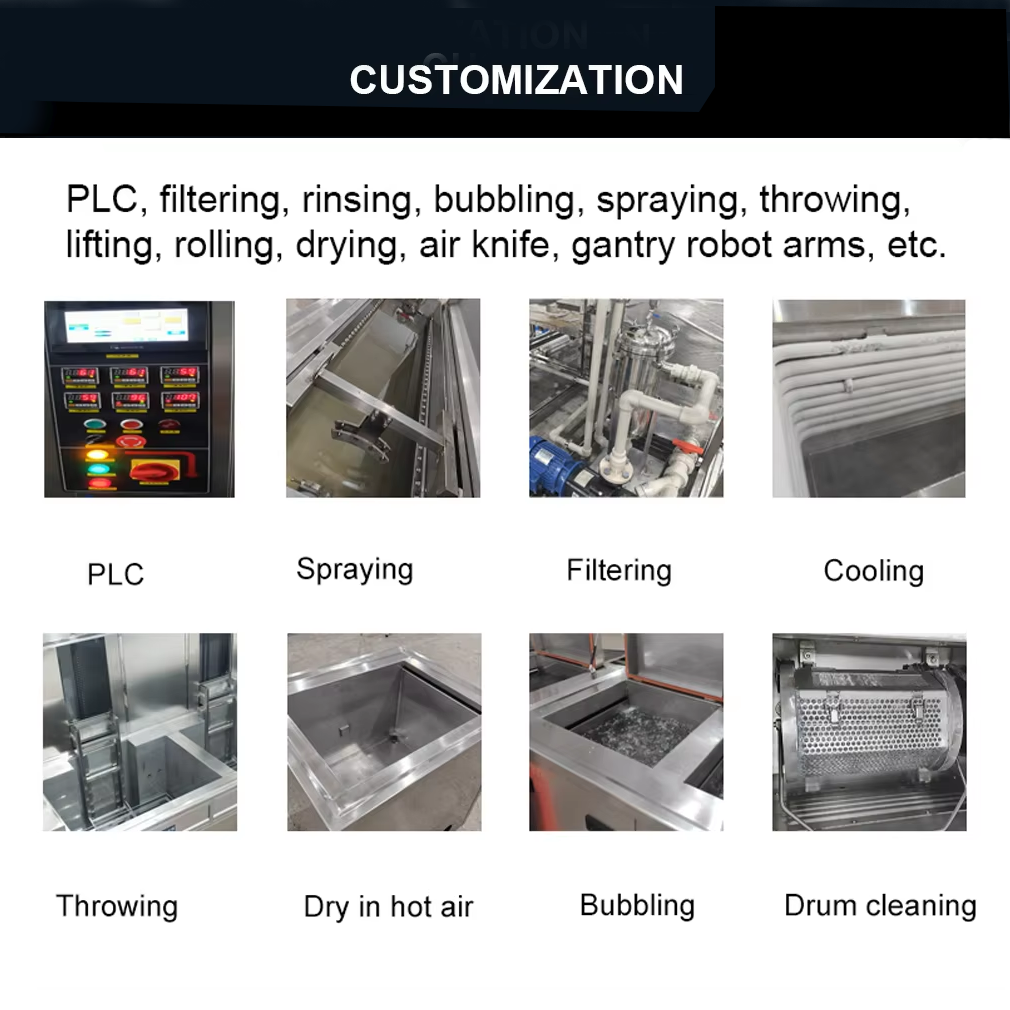

9. Function customized: Full-Automatic Equipment, Through-Type equipment, Filtration circulation system, High-pressure spraying, Bubbling, Drying, Lifting, Throwing, Cooling, Slow pulling and other functions.

Additional information

| Weight | 1800 kg |

|---|---|

| Dimensions | 1005 × 130 × 180 cm |